Project Cooperation

Our competitive advantage

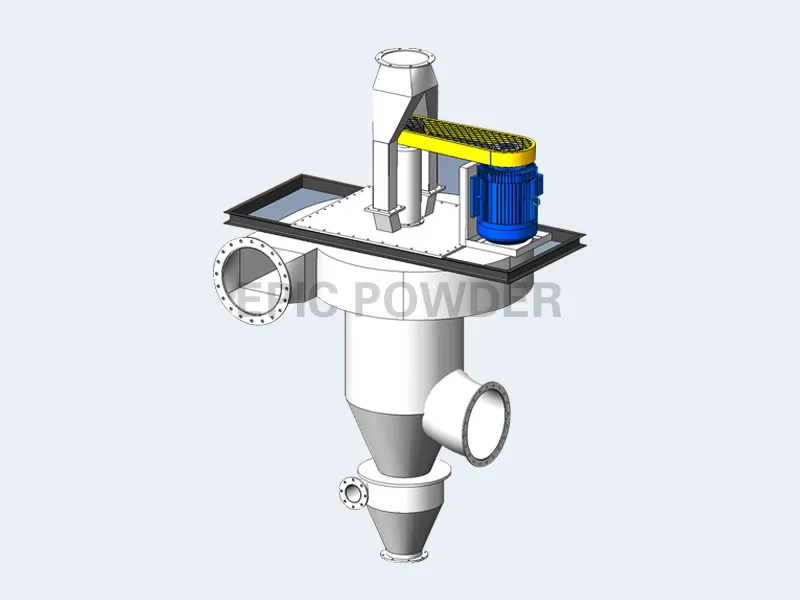

Our company is committed to the design and manufacture of powder processing equipment, as well as a variety of powder processing projects consulting and services. Our main equipment are: fluidized bed air mill, disc air mill, rotor impact mill, graded impact mill, powder special ball mill, air classifier, ultrafine powder mixer, ultrafine powder disperser, particle surface treatment equipment. We have accumulated rich experience in developing solutions for customers in various industries such as mineral, chemical, new materials, food, feed, medicine, etc. We have a professional test center and laboratory in Qingdao, ready to provide you with sample testing, scientific research assistance, technical consultation, and explore various difficult problems of powder processing with you. We have not only senior engineers in the industry, but also expert consultants from Germany and Australia.

EPIC powder · Excellence

Build a powder equipment manufacturing base, win the wisdom of the trend!

Our dedicated sales team acts as a crucial link. They facilitatingeffective communication and seamless collaboration among differentdepartments. They provide valuable industry insights. And ensuring youstay informed about the latest trends and developments. with theirexpertise and commitment to exceptional customer service, they guideyou through a positive purchasing experience. Trust our sales team to beyour reliable partner in achieving your goals.

We adhere to stringent quality assurance processes at every stage ofmanufacturing. lt helps in ensuring each piece of machinery meets thehighest industry standards. our certifications and ongoing improvementinitiatives further reinforce our commitment to high-quality machines.

Field of cooperation

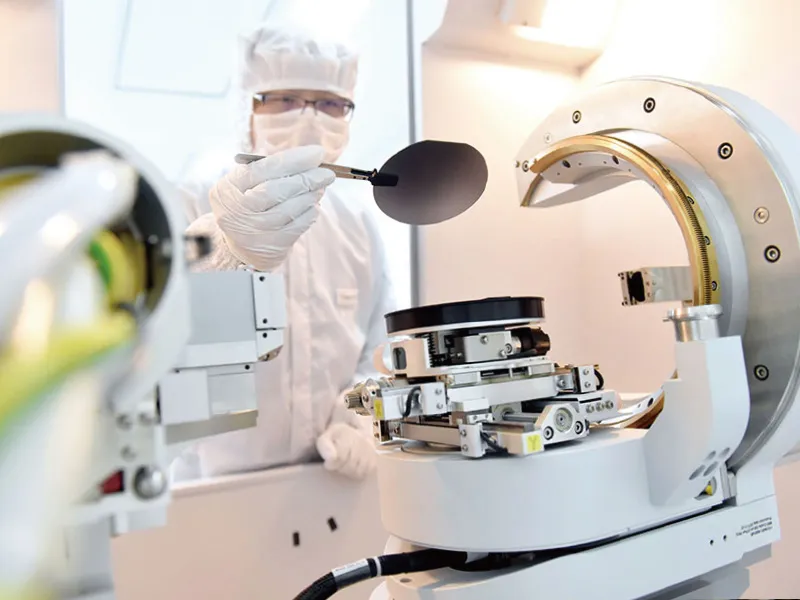

Battery Material

Building Materials & Solid Waste

Cosmetics

Environmental Desulfurization

Fine Chemical Industry

Food

Health Products

High-tech Material

Medicine

Nonmetallic ore

Pigments & Dyes

Powder Metallurgy

Partner Companies

EPIC offers the best quality and good service in 160 countries and areas in the world.

Our Products

Industry we serve

Why Air Classifier Outperform Other Classification Systems

ITC series airflow classifier

Performance characteristics and development trends of air flow classifiers

FAQ

EPIC Powder Machinery has been engaged in the production of powder equipment for more than 20 years, focusing on technology research and development and product control. The high requirements for product quality are also the absolute requirements for our customers to be serious and responsible. We are deeply aware that product quality is the foundation of a company's long-term development. Because of this, our requirements for quality control must be comprehensive, multi-level, and high standards.

About two months. Our machines are a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.

By ship. After the production of the machines is completed, we first package and put it into a container, and ship it by sea. (Cost allocation).

EPIC Powder Machinery producing machines are non-standard customized products. We select and design the plan according to the customer's needs, and make proposals based on the experimental data of the customer's material or past experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet the production requirements of customers, and we provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.

EPIC Powder Machinery's products are very cost-effective in the same industry. From product quality, performance, price to our after-sales service, we tailor-made for customers in accordance with the industry's high standards. EPIC is committed to achieving the integration of production and research, while repaying the trust of customers with high-quality services.

EPIC Powder Machinery has a large technical team that can provide on-site installation guidance and online installation guidance, from receiving the goods to putting it into production, to solve the customer's worries.

Our company has passed ISO quality management system certification and intellectual property system certification. Equipment exported to the EU can also provide CE certification, and equipment exported to Russia can provide EAC certification.

EPIC Powder Machinery has a large technical team that can provide on-site installation guidance and online. installation guidance, from receiving the goods to putting it into production, to solve the customer's worries.

EPIC Powder Machinery is committed to building a professional service team for customers. After-sales service is our key area. We can provide you with a 1 year warranty and professional on-site installation technical guidance. Each set of products will be there is a set of fragile accessories, at the same time, EPIC can provide you with a free production line upgrade program for the products you purchase.

About two months. Our machines are a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.

By ship. After the production of the machines is completed, we first package and put it into a container, and ship it by sea. (Cost allocation)

EPIC Powder Machinery producing machines are non-standard customized products. We select and design the plan according to the customer's needs, and make proposals based on the experimental data of the customer's material or past experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet the production requirements of customers, and we provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.