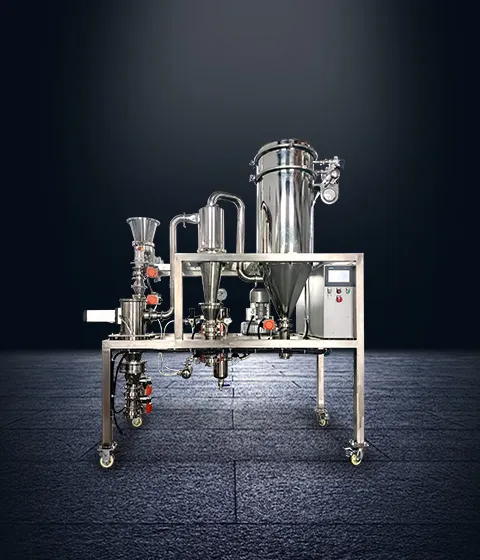

Air Classifier HTS-Lab

- Three-in-one combined structure,integrate jetmill, air classifier and impact mills.

- The equipment has compact structure, convenient operation and conversion, and small installation space.

- The key parts can be made of all-ceramic structure, zero metal pollution.

- The grinding process can be protected by inert atmosphere, which has a high safety factor.

- Especially suitable for research and development and testing of new products in scientific research institutes, college laboratories, factory research institutes, and factory laboratories.

Contact EPIC Powder Machinery

Send Us A Message

Description of Air Classifier Lab

The Air Classifier Lab is a modern facility. It specializes in advanced particle size classification. This lab can achieve a particle size of D97: 2μm. It’s perfect for applications that need precise and fine material separation. The equipment can produce between 0.5 kg and 1 kg per hour. This makes it great for research and small-scale production. The Air Classifier Lab uses high-quality materials such as 304 stainless steel, alumina, and zirconia ceramic lining. This design ensures it’s durable and reliable for various processing settings. It also provides protective gas options like nitrogen and argon. These gases help improve the quality and purity of classified materials.

Working Principle

The material enters the jet mill (impact mill) through the automatic feeding system and grinds the material to a suitable particle size. The high-speed rotating classifying wheel realizes the separation of different particle sizes. The qualified products enter the cyclone collector for collection, and the coarse particles return to the grinding area. If it is necessary to classify the materials separately, combine the air classifier unit, and adjust the impeller speed through the frequency converter to achieve product classification with different particle sizes.

Features

- Three-in-one combined structure,integrate jetmill, air classifier and impact mills.

- The equipment has compact structure, convenient operation and conversion, and small installation space.

- The key parts can be made of all-ceramic structure, zero metal pollution.

- The grinding process can be protected by inert atmosphere, which has a high safety factor.

- Especially suitable for research and development and testing of new products in scientific research institutes, college laboratories, factory research institutes, and factory laboratories.

Contact EPIC Powder Machinery

Send Us A Message

Industry we serve

Why Air Classifier Outperform Other Classification Systems

ITC series airflow classifier

Performance characteristics and development trends of air flow classifiers

FAQ

EPIC Powder Machinery has been engaged in the production of powder equipment for more than 20 years, focusing on technology research and development and product control. The high requirements for product quality are also the absolute requirements for our customers to be serious and responsible. We are deeply aware that product quality is the foundation of a company's long-term development. Because of this, our requirements for quality control must be comprehensive, multi-level, and high standards.

About two months. Our machines are a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.

By ship. After the production of the machines is completed, we first package and put it into a container, and ship it by sea. (Cost allocation).

EPIC Powder Machinery producing machines are non-standard customized products. We select and design the plan according to the customer's needs, and make proposals based on the experimental data of the customer's material or past experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet the production requirements of customers, and we provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.

EPIC Powder Machinery's products are very cost-effective in the same industry. From product quality, performance, price to our after-sales service, we tailor-made for customers in accordance with the industry's high standards. EPIC is committed to achieving the integration of production and research, while repaying the trust of customers with high-quality services.

EPIC Powder Machinery has a large technical team that can provide on-site installation guidance and online installation guidance, from receiving the goods to putting it into production, to solve the customer's worries.

Our company has passed ISO quality management system certification and intellectual property system certification. Equipment exported to the EU can also provide CE certification, and equipment exported to Russia can provide EAC certification.

EPIC Powder Machinery has a large technical team that can provide on-site installation guidance and online. installation guidance, from receiving the goods to putting it into production, to solve the customer's worries.

EPIC Powder Machinery is committed to building a professional service team for customers. After-sales service is our key area. We can provide you with a 1 year warranty and professional on-site installation technical guidance. Each set of products will be there is a set of fragile accessories, at the same time, EPIC can provide you with a free production line upgrade program for the products you purchase.

About two months. Our machines are a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.

By ship. After the production of the machines is completed, we first package and put it into a container, and ship it by sea. (Cost allocation)

EPIC Powder Machinery producing machines are non-standard customized products. We select and design the plan according to the customer's needs, and make proposals based on the experimental data of the customer's material or past experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet the production requirements of customers, and we provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.