Dry dust removal systems should take measures to prevent and control dust explosions based on the explosion characteristics of dust. It’s according to Article 4.2 of the AQ4273-2016 Safety Technical Specifications for Dust Removal Systems in Dust Explosion Hazardous Locations. To reduce the risk of explosions, one or more of the following explosion-proof devices should be selected:

Explosion relief device: Before the explosion pressure exceeds the resistance threshold of the dust collector and air duct, an explosion relief device discharges explosion byproducts, preventing damage to the dust collector and air duct.

Inerting device: Inert gas or powder is introduced into the dust collector to neutralize the explosiveness of combustible dust.

Explosion-proof device: Installed on the air duct, an explosion-proof device prevents the spread of flames and explosion waves within a specified range.

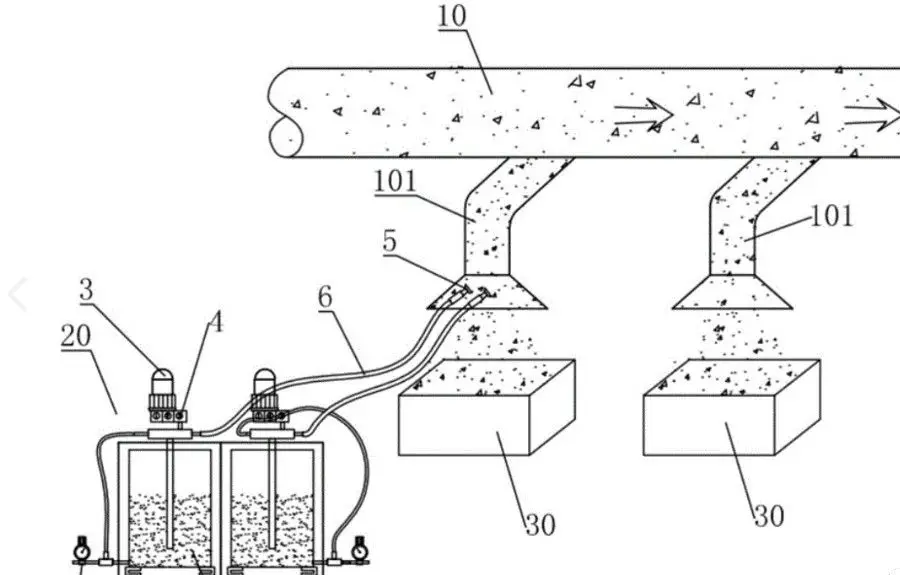

Explosion suppression device: Installed on the air duct and/or dust collector, this device releases a physical or chemical fire-extinguishing medium at the moment of an explosion to suppress its development or spread.

1. Explosion Relief Device

Explosion Relief: The explosion relief port design of the dust collector must comply with relevant regulations, and the explosion relief components used must be tested and certified. It is recommended to engage a qualified third-party design agency for the design. If an explosion relief component is used for the dust collector, the commonly referenced standards for calculating the explosion relief area include GB/T 15605-2008, EN 14491-2012, and NFPA 68-2013. However, existing national standards for dust collectors include specific requirements, and manufacturers must enhance explosion relief and explosion suppression measures accordingly.

2. Explosion-Proof Device

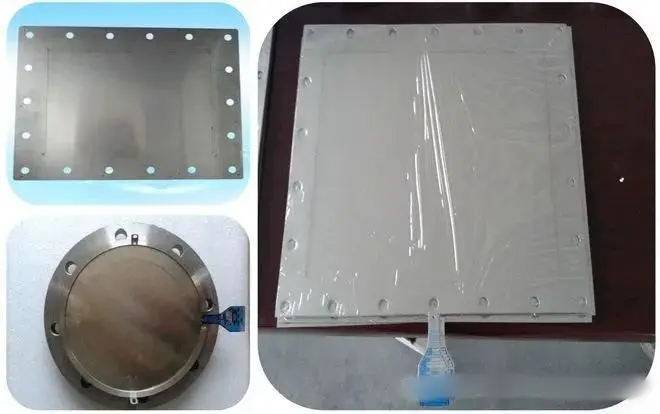

Explosion-Proof Technology: Explosion-proof technology primarily involves explosion control measures that prevent the spread of explosions. This ensures they do not extend to protected areas. The most common explosion-proof device is the explosion-proof valve, which is widely used internationally due to its simplicity and reliability.

The working principle of the explosion-proof valve is to utilize the pressure generated during an explosion to push the valve core. In this case, it can block the propagation of explosion flames and pressure. The selection of an explosion-proof valve depends on factors like the dust explosion characteristics, the explosion resistance of the dust collector, and the air duct specifications.

The explosion-proof valve must be installed on the main air duct outside the factory building, and its activation switch should be protected and interlocked with the control system of the dust removal system to ensure safety.

3. Explosion Suppression Device

The explosion suppression device is primarily sourced from foreign manufacturers. Its main principle is to detect an explosion in its early stages and rapidly release suppression agents to reduce or prevent its spread. It can generally be installed in any hazardous location. However, its selection should be based on factors such as dust explosion characteristics, the explosion resistance of the dust collector and air duct. Interlocking requirements with the dust collector’s control system to ensure effective operation.

4. Inerting Device

When a dust collector uses inert gas as a medium, it’s important to control the oxygen content inside the system. The flow rate of powder introduced into the central dust removal system should not exceed 50%. When an inerting device is integrated into the dust collector, an explosion-proof device with a monitoring function should be installed. This device should be capable of automatically triggering an alarm in case of abnormal operation to ensure timely intervention.

Conclusion

To ensure the safety of dust removal systems in explosion-hazardous environments, it is crucial to implement appropriate explosion protection measures. Explosion-proof devices are essential for ensuring the safety of dust removal systems in explosion-prone environments. Explosion relief, explosion-proof, explosion suppression, and inerting devices each play a vital role in mitigating explosion risks. Proper selection, installation, and interlocking with the dust collector’s control system are essential for effective protection. By adhering to relevant standards and best practices, industries can significantly enhance workplace safety and minimize potential explosion hazards.

Choose Epic Powder for efficient, energy-saving, and environmentally friendly powder processing solutions!

Contact us to learn more about our products!