At Epic Powder Machinery, we are not only committed to delivering advanced powder processing technologies, but also to improving day-to-day operational efficiency through smart, hands-on innovations. The following Belt Conveyor Roller Replacement Bracket is one such example.

Fabrication Method

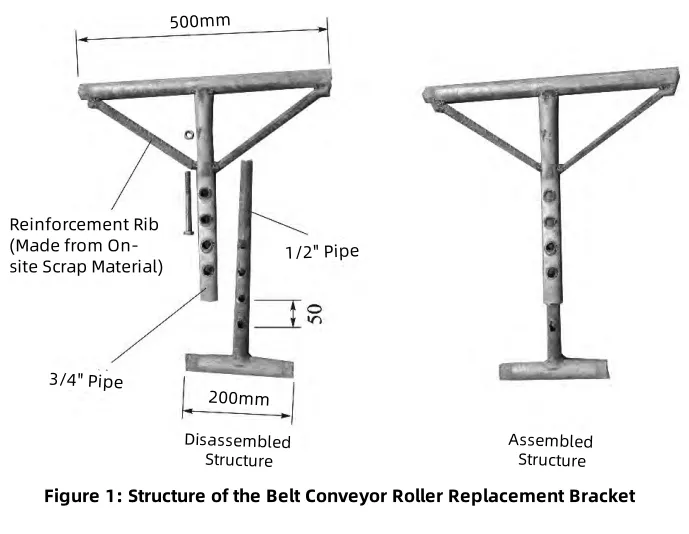

The traditional method for replacing rollers on a belt conveyor involves using a crowbar to pry up the belt at the location of the roller to be replaced, while another person quickly removes the old roller and replaces it with a new one. This method is time-consuming, labor-intensive, and poses safety risks. Based on years of production experience, we have designed and fabricated a homemade belt roller replacement bracket. This bracket is designed based on the principle of leverage, and its structure is shown in Figure 1. The bracket is a welded assembly, consisting of two parts with adjustable height to suit different work requirements. A handle can also be welded onto the 3/4″ pipe for easier operation.

Usage Method

One person inserts the bracket diagonally under the belt at the location where the roller needs to be replaced. By pulling the bracket backward using leverage, it applies vertical force between the upper and lower belts, lifting the belt. At this point, the roller can be conveniently removed and replaced. With this tool, the previous labor-intensive, two-person operation is reduced to a simple, one-person task. This not only saves time during replacement but also improves safety and efficiency.

Driven by Innovation and Practicality

At Epic Powder Machinery, we believe that innovation isn’t limited to high-end equipment — it’s also about creating simple tools that make a big difference. We continuously explore ways to enhance safety, efficiency, and ease of operation across all aspects of powder processing.