Ball milling and classifying production line is a commonly used powder making equipment. It’s mainly used in mining, metallurgy, chemical industry, building materials and other industries. This article will introduce the basic concept of ball milling and classifying production line. It also explores the application in non-metallic minerals. Let’s find out how to choose a line that suits you.

1. What is a ball milling and classifying production line?

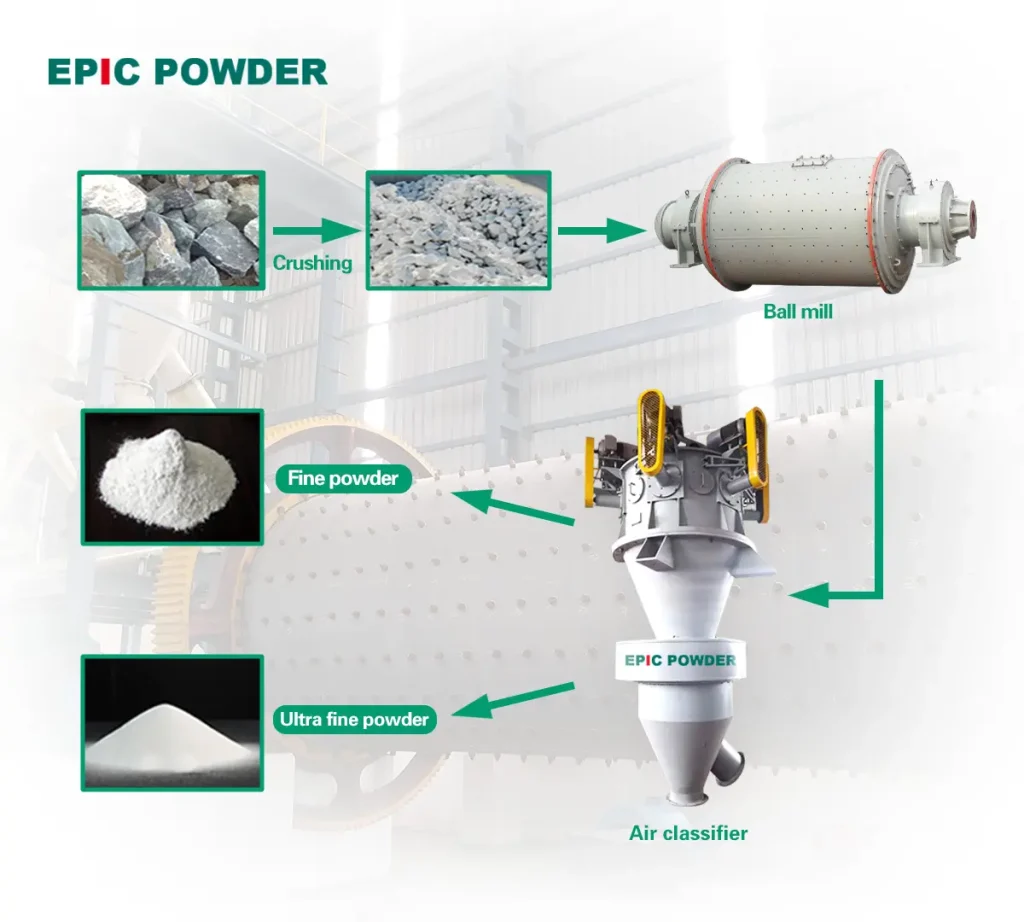

The ball milling and classifying production line is a powder making equipment composed of two parts: a ball mill and an air classifier. The ball mill grinds the raw materials to generate powder particles, while the air classifier classifies the powder according to the particle size through air movement and centrifugal force, thereby obtaining the final product within the required particle size range.

2. Application of ball milling and classifying production line in non-metallic minerals

In the field of non-metallic minerals, ball milling and classifying production lines are widely used in the field of ultra-fine grinding. For example:

1. Heavy calcium carbonate: Heavy calcium carbonate is a kind of ultra-fine powder with high whiteness and high gloss. It’s widely used in plastics, rubber, paint and other industries.

2. Titanium dioxide: Titanium dioxide is a white pigment with a wide range of applications. They can serve as fillers and colorants in paints, plastics, paper and other industries.

3. Abrasives: Ball milling and classifying production lines can also be used to manufacture abrasives, such as cutting tools, grinding tools, polishing tools, etc., which are used in metal processing, glass processing and other industries.

3. Which non-metallic minerals are suitable for ultra-fine grinding of ball milling and classifying production lines?

Ball milling and classifying production lines are suitable for ultra-fine grinding of the following types of non-metallic minerals:

1. Materials with lower hardness

If the raw material hardness is higher, a higher-power ball mill is required for production, which will increase the cost. Therefore, the ball milling and classifying production line is suitable for materials with lower hardness, such as heavy calcium carbonate, talcum powder, etc.

2. Materials that require high precision

The line can produce fine powders with relatively uniform particle size, which is particularly suitable for materials that require high precision, such as bauxite, titanium dioxide, etc.

3. Materials that require high quality

Since the line can separate fine particles through air classification, high-quality products can be obtained, such as titanium dioxide, aluminum borate, etc.

4. How to choose a ball milling and classifying production line that suits you?

The following aspects need to be considered when choosing a ball milling and classifying production line that suits you:

1. Raw material characteristics

Different raw materials require different ball milling and classifying production lines. For example, raw materials with higher hardness require a ball mill with higher power. Raw materials with higher fineness require a finer line.

2. Production capacity

When choosing a ball milling and classifying production line that suits you according to production needs, you need to consider production capacity. Determine the specifications, quantity and configuration of the required equipment according to production volume and cycle.

3. Technical level

When choosing a supplier of a ball milling and classifying production line, you need to pay attention to its technical level, product quality and after-sales service to ensure the stability and long-term operational efficiency of the equipment.

4. Cost control

When choosing a line that suits you, you also need to consider the cost of the equipment, including the cost of purchase, use and maintenance. On the premise of ensuring equipment quality and production efficiency, reducing costs as much as possible will help the economic benefits of the enterprise.

5. Future development plan

When choosing a ball milling and classifying production line, you also need to consider future development plans, estimate future market demand and production capacity expansion factors, so as to adjust and optimize the configuration and layout of the equipment.

In short, choosing a ball milling and classifying production line that suits you requires comprehensive consideration of multiple factors, and making decisions on the basis of ensuring equipment quality, production efficiency and cost control to achieve the optimal production goal.

As a well-established brand in the industry, Epic Powder Machinery is committed to customer-centricity, quality, and innovation. We are your reliable partner for long-term success.

Choose Epic Powder for efficient, energy-saving, and environmentally friendly powder processing solutions!

Contact us to learn more about our products!