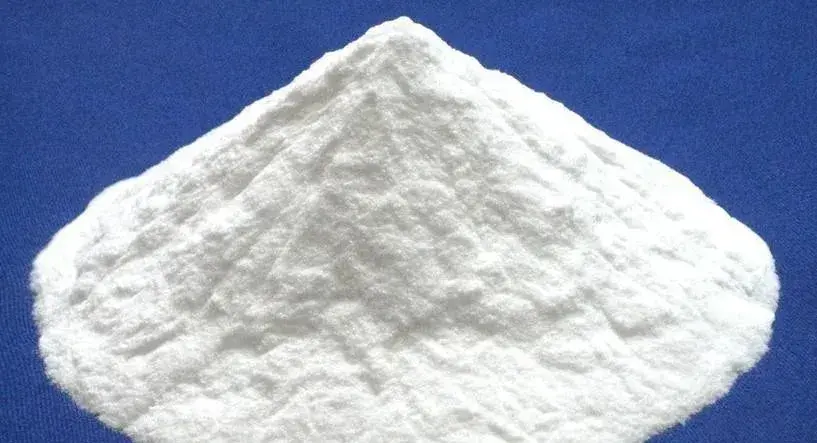

Photovoltaic quartz sand refers to high-purity quartz sand that meets the requirements of the photovoltaic industry. It is one of the important raw materials in photovoltaic power generation systems and is primarily used to produce silicon wafers for photovoltaic panels. The purity and quality of it directly affect the performance and lifespan of photovoltaic panels. Therefore, its production, processing, and use must adhere to strict requirements.

1. Quality Requirements for Photovoltaic Quartz Sand

Chemical Composition: The chemical composition of photovoltaic quartz sand should meet national standards. The silicon dioxide content should be ≥ 99.9%. The impurity content (such as iron, aluminum, calcium, etc.) should be < 0.1%.

Particle Size Distribution: The particle size distribution should be uniform. Generally, the particle size should range between 0.1-0.3mm, and the cumulative mass fraction in this range should be ≥ 90%.

Impurity Content: The impurity content of it should be < 0.02%, with alkali metal content (such as potassium, lithium, and sodium) being < 2.5μg/g.

Purity Grade: The purity grade of it must be very high. It needs to reach 3N or above (SiO2 = 99.98%) to ensure the performance and lifespan of photovoltaic panels.

Anti-Crystallization: The anti-crystallization properties of photovoltaic quartz sand are crucial. The quartz sand must not easily precipitate crystals at high temperatures, ensuring the stability and lifespan of photovoltaic panels.

Surface Treatment: Photovoltaic quartz sand usually requires surface treatment to enhance its compatibility with resin and reduce surface activity. This can improve the quality and performance of photovoltaic panels.

Hardness: The hardness of it must meet national standards, generally falling within the range of 7-8 on the Mohs scale.

Color: The color of it should be white or light yellow, uniform, and free of any other colors.

Grain Shape: Photovoltaic quartz sand should have a granular shape with a smooth surface, free of sharp corners or dust.

In summary, the technical requirements and standards for photovoltaic quartz sand are designed to ensure its purity, stability, particle size distribution, and low impurity content. These standards are essential to meet the performance and quality control needs of photovoltaic power generation products.

2. Preparation of Photovoltaic Quartz Sand

The preparation of photovoltaic quartz sand involves several key steps, including ore selection, crushing, grinding, screening, cleaning, and other processes. The specific process is as follows:

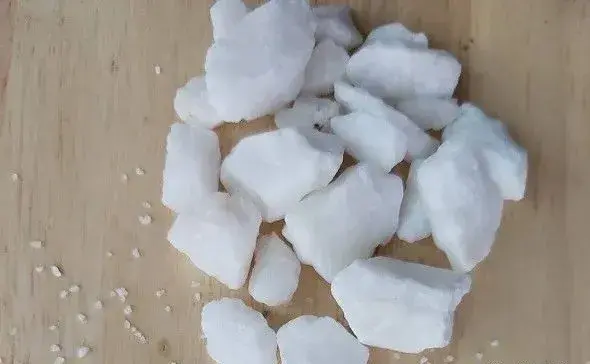

Ore Selection: High-quality quartz ore that meets the requirements of the photovoltaic industry is selected. The ore should have low impurities, such as iron, aluminum, and calcium, and a high silicon dioxide content.

Crushing: Large pieces of quartz ore are broken into smaller pieces for further grinding.

Grinding: The crushed quartz ore is placed in a grinder, where grinding media (such as steel balls) are added. The ore is ground to a specific fineness.

Screening: The ground quartz sand is screened through a sieve to remove oversized or undersized particles, ensuring a uniform particle size.

Cleaning: The screened quartz sand is cleaned to remove surface impurities and dust, ensuring the purity and quality of the final product.

3. Application of Photovoltaic Quartz Sand

Photovoltaic quartz sand is a critical raw material in photovoltaic power generation systems. It’s primarily used in the production of silicon wafers for photovoltaic panels. Its quality directly influences the performance and lifespan of photovoltaic panels. This is why its production, processing, and use must meet stringent standards.

Silicon wafers are one of the core components in photovoltaic panels, and their quality determines the power generation efficiency and service life of the panels. Photovoltaic quartz sand is one of the key raw materials for making silicon wafers. Its purity and quality are essential for ensuring the overall performance and reliability of photovoltaic panels. Thus, the production and processing must strictly adhere to industry standards to maintain the highest quality and purity.

IV. Development Prospects of Photovoltaic Quartz Sand

With the global demand for clean energy steadily rising, the photovoltaic power generation industry is experiencing rapid growth. As one of the essential raw materials in this sector, the demand for it is also increasing. Looking ahead, the continuous development of the photovoltaic industry will drive sustained growth in the market for photovoltaic quartz sand.

Moreover, with advancements in science and technology, the production and processing techniques for photovoltaic quartz sand will continue to improve, enhancing its quality and performance. This progress, combined with the expanding market demand, indicates that the its industry has a promising future with broad development prospects.

Choose Epic Powder air classifier for efficient, energy-saving, and environmentally friendly photovoltaic quartz sand processing solutions!

Contact us to learn more about our products!