Your trusted EPIC powder equipment

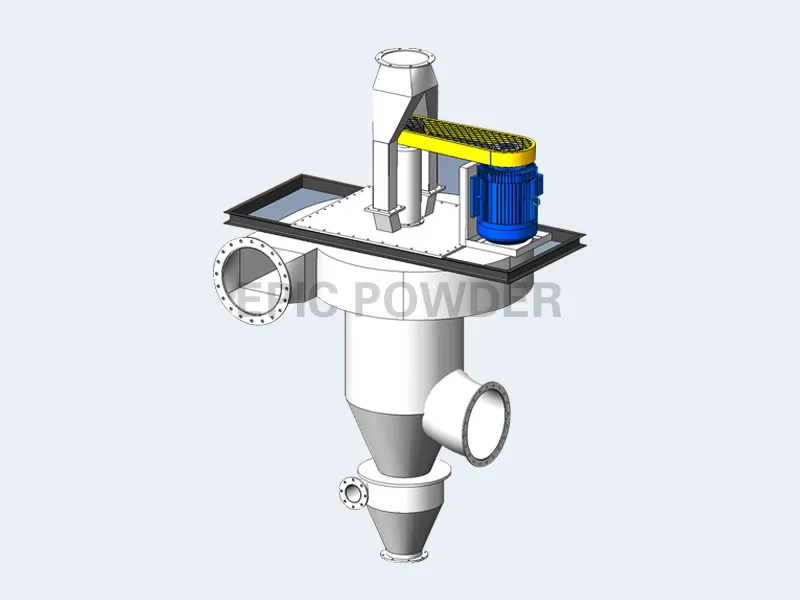

Powder Separator MBS

- The hierarchical structure design is unique, low pressure, low energy consumption.

- It is very good for apex cutting of ultra-fine products and medium-fine products.

- Applicable to a wide range of particle sizes, the coarsest can reach 200 microns.

- There are different models to meet different output, and the feeding capacity of the largest model can reach 800t/h.

- Wear-resistant design, can handle powder products with extremely high hardness.

- The design of internal air circulation can reduce investment and save floor space.

- It can be combined with a ball mill to form a closed-circuit production system for grinding various materials.

Contact EPIC Powder Machinery

Send Us A Message

Working Principle

MBS series air classifier is jointly designed by our German experts and British experts, and is specially used for efficient dry classification of D97: 8-200 micron powder. The classifier, cyclone collector, dust collector and induced draft fan form a complete classification system. The feeding port of the classifier is at the top of the classifier. The feed enters the classifier from the top inlet under the action of gravity, and then falls onto the centrifugal dispersion disc of the classifying wheel. The material will be evenly dispersed, dispersed to the baffle ring and down into the grading area. Classification air enters the scroll housing, passes the guide vanes, and inwards to the classification wheel. The fine powder is carried by the airflow into the classifying wheel, and then enters the cyclone collector or dust collector with the airflow, while the coarse powder will be repelled by the centrifugal force of the classifying wheel and fall into the lower body of the classifier.

Features

- The hierarchical structure design is unique, low pressure, low energy consumption.

- It is very good for apex cutting of ultra-fine products and medium-fine products.

- Applicable to a wide range of particle sizes, the coarsest can reach 200 microns.

- There are different models to meet different output, and the feeding capacity of the largest model can reach 800t/h.

- Wear-resistant design, can handle powder products with extremely high hardness.

- The design of internal air circulation can reduce investment and save floor space.

- It can be combined with a ball mill to form a closed-circuit production system for grinding various materials.

Contact EPIC Powder Machinery

Send Us A Message

Technical Parameters

| Parameter / Model | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drive power (kW) | 5.5 | 11 | 15 | 22 | 37 | 45 | 75 | 110 | 132 | 160 | 185 | 220 | 280 | 320 | 380 | 475 | 540 | 630 |

| Air flow rate(m³/h) | 2800 | 4700 | 8600 | 15200 | 23400 | 31000 | 49000 | 74000 | 107000 | 150000 | 190000 | 237000 | 288000 | 344000 | 402000 | 469000 | 536000 | 606000 |

| Fineness D97 (μm) | 8 | 9 | 10 | 13 | 14 | 16 | 18 | 20 | 25 | 27 | 28 | 29 | 31 | 33 | 34 | 35 | 37 | 38 |

| Max. feed rate (t/h) | 4 | 6.6 | 12.1 | 12.3 | 32.8 | 43 | 68 | 100 | 140 | 210 | 260 | 330 | 400 | 480 | 560 | 650 | 750 | 840 |

Industry we serve

Why Do Fine Particles Agglomerate?

Classification and Performance Effects of Different Zinc Oxides

AP-Rubber Plas Exhibition

FAQ

EPIC Powder Machinery has been engaged in the production of powder equipment for more than 20 years, focusing on technology research and development and product control. The high requirements for product quality are also the absolute requirements for our customers to be serious and responsible. We are deeply aware that product quality is the foundation of a company's long-term development. Because of this, our requirements for quality control must be comprehensive, multi-level, and high standards.

About two months. Our machines are a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.

By ship. After the production of the machines is completed, we first package and put it into a container, and ship it by sea. (Cost allocation).

EPIC Powder Machinery producing machines are non-standard customized products. We select and design the plan according to the customer's needs, and make proposals based on the experimental data of the customer's material or past experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet the production requirements of customers, and we provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.

EPIC Powder Machinery's products are very cost-effective in the same industry. From product quality, performance, price to our after-sales service, we tailor-made for customers in accordance with the industry's high standards. EPIC is committed to achieving the integration of production and research, while repaying the trust of customers with high-quality services.

EPIC Powder Machinery has a large technical team that can provide on-site installation guidance and online installation guidance, from receiving the goods to putting it into production, to solve the customer's worries.

Our company has passed ISO quality management system certification and intellectual property system certification. Equipment exported to the EU can also provide CE certification, and equipment exported to Russia can provide EAC certification.

EPIC Powder Machinery has a large technical team that can provide on-site installation guidance and online. installation guidance, from receiving the goods to putting it into production, to solve the customer's worries.

EPIC Powder Machinery is committed to building a professional service team for customers. After-sales service is our key area. We can provide you with a 1 year warranty and professional on-site installation technical guidance. Each set of products will be there is a set of fragile accessories, at the same time, EPIC can provide you with a free production line upgrade program for the products you purchase.

About two months. Our machines are a non-standard customized product, and the production of each main component is put into production after signing the contract. Therefore, our production cycle is about 1-2 months.

By ship. After the production of the machines is completed, we first package and put it into a container, and ship it by sea. (Cost allocation)

EPIC Powder Machinery producing machines are non-standard customized products. We select and design the plan according to the customer's needs, and make proposals based on the experimental data of the customer's material or past experience and data. After meeting the customer's requirements, start manufacturing. Therefore, our products meet the production requirements of customers, and we provide customers with comprehensive guidance and installation services, and strive to solve customers' production and installation problems.